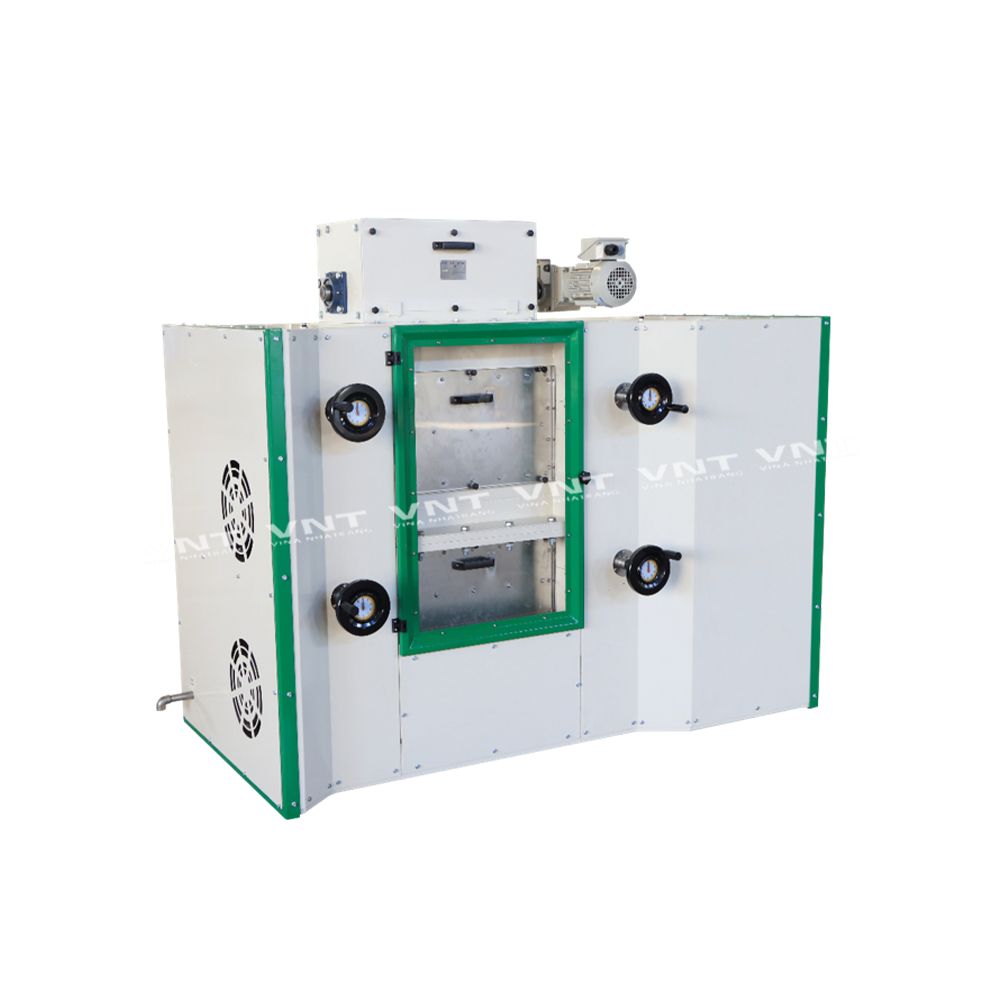

Industrial Coffee Mill Overview: Boost Efficiency and Top Quality

In the affordable landscape of coffee manufacturing, picking the best industrial coffee mill plays an essential function in enhancing both performance and product top quality. Comprehending the subtleties of numerous grinder types and essential functions-- such as personalized work setups and durable construction-- can dramatically affect the final taste account of the coffee.

Understanding Grinder Types

When selecting a commercial coffee grinder, comprehending the different types offered is vital for enhancing both flavor extraction and functional effectiveness. The two primary sorts of mills are blade grinders and burr grinders. Blade mills make use of sharp blades that slice coffee beans right into inconsistent dimensions, causing uneven removal and potentially unfavorable flavors. While blade mills are typically more ideal and budget friendly for small procedures, they are normally not recommended for commercial use.

Eventually, picking the right kind of grinder is indispensable to maintaining high quality and effectiveness in coffee manufacturing, making it critical for organizations to purchase high-quality burr mills for optimum results.

Secret Attributes to Consider

Choosing a commercial coffee grinder needs mindful factor to consider of a number of vital features that can substantially affect both efficiency and the overall coffee experience. One of the main facets to evaluate is the grinding device. Burr grinders are typically liked over blade mills, as they give a regular grind size, which is important for optimum removal and taste.

One more important function is the grinder's capacity. A versatile mill with several setups enables you to tailor the grind dimension to different brewing methods, enhancing the coffee's taste account.

The building and construction material additionally plays a duty in resilience and maintenance. Stainless-steel parts often offer long life and are much easier to clean, which is important for maintaining health requirements. Lastly, evaluate the grinder's noise degree, particularly in a busy café or manufacturing setting, where too much sound can be turbulent. Purchasing a grinder that stabilizes these features can significantly boost both operational performance and the high quality of the coffee served.

Optimizing Grinding Refine

To accomplish the most effective cause coffee preparation, optimizing the grinding process is important. The work dimension dramatically affects removal, flavor, and general top quality of the made coffee. Different brewing techniques call for details grind dimensions; for instance, coffee requires a great grind, while French press necessitates a crude appearance. Understanding the relationship between grind size and developing approach is the initial step in optimization.

Additionally, keeping track of the grinding speed can maximize the procedure. Slower grinding often produces less heat, preserving delicate flavors and aromas. Conversely, faster grinding may create excessive heat, adversely influencing the coffee's top quality.

Upkeep and Treatment Tips

Appropriate maintenance and care of industrial coffee mills are necessary for ensuring ideal efficiency and long my latest blog post life. Normal cleaning is the foundation of upkeep; deposit build-up can impact flavor and grinding efficiency. It is a good idea to clean the grinder after each use, wiping down the outside and eliminating any type of coffee grounds from the burrs.

In addition, evaluate the grinding burrs for deterioration. Dull burrs can endanger work consistency, so they should be changed as needed. Industrial Coffee Grinder. Regularly adjusting the grinder is also crucial, as this click reference keeps the preferred grind dimension for different brewing approaches

Lubrication of moving components need to be executed according to the maker's specifications, as this lowers friction and lengthens the life of the devices. It is important to use food-grade lubricating substances to make sure safety and conformity with health and wellness guidelines.

Lastly, keep the mill in a stable and completely dry environment to avoid rust and rust. By adhering to these upkeep and treatment suggestions, drivers can enhance the effectiveness of their commercial coffee grinders while making certain premium output and prolonged operational life.

Return on Investment Evaluation

Reviewing the return on investment (ROI) for industrial coffee mills is crucial for companies looking for to enhance their coffee manufacturing capacities. An extensive ROI analysis aids establish the financial stability of buying high-grade mills, their explanation permitting businesses to weigh the initial prices versus potential gains.

Examine the purchase rate of the grinder, including installment and any type of required alterations to existing framework. High-performance grinders commonly lead to minimized grinding time and enhanced throughput, which can significantly improve productivity.

In addition, think about the influence on item quality. Industrial Coffee Grinder. Superior mills yield an even more regular work size, which can enhance flavor accounts and customer complete satisfaction, ultimately driving sales. By raising the quality of the end product, services can validate greater prices, leading to boosted revenue

Final Thought

In summary, a commercial coffee grinder plays a critical function in boosting both effectiveness and item quality within coffee manufacturing. By picking premium burr mills geared up with necessary features such as adjustable work setups and resilient building and construction, organizations can guarantee ideal taste extraction. Additionally, routine maintenance is critical for sustaining mill efficiency and making best use of client satisfaction. Ultimately, the strategic investment in a trustworthy mill adds substantially to boosted revenue and competition in the coffee sector.

In the affordable landscape of coffee production, choosing the best industrial coffee mill plays a pivotal duty in enhancing both efficiency and product quality. The 2 key kinds of grinders are blade grinders and burr mills. Within the burr mill category, there are flat burr mills and conical burr grinders, each with its benefits. Burr grinders are typically chosen over blade grinders, as they give a regular grind dimension, which is essential for optimum extraction and flavor.

In recap, an industrial coffee mill plays an essential function in enhancing both performance and product quality within coffee manufacturing.

Comments on “How an Industrial Coffee Grinder Enhances Flavor Consistency”